Our top machine maintenance explainers, best practices, technologies, and more.

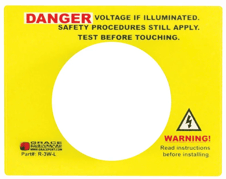

Maintenance Starts with Lockout/Tagout

All machine maintenance and repair should begin with the effective and safe implementation of lockout/tagout (LOTO) procedures. This post from Airline's machine safety division, MPSA, reviews considerations and products to support the effective and safe implementation of LOTO procedures.

FEATURED LOTO TECHNOLOGIES

Why Choose Airline for Service & Repair?

Our ISO-certified facilities, experienced team of factory-trained bench mechanics, and a fully-equipped fleet of service trucks are just a few reasons why you should choose Airline.

Tutorial: How to Take a Hydraulic Oil Sample

Oil is a hydraulic system's lifeblood, and much like a blood sample, oil samples get analyzed to tell us important information that often goes undetected until system failure. Approximately 85% of hydraulic component failures result from contaminated oil, so today, I'll teach you one way to take an oil sample so that you can prevent these failures from happening to you!

FEATURED FLUID RECONDITIONING TECHNOLOGIES

Let Red Fix it Right

Airline's Red Pallet Program lets you schedule your repair pickups easily online. Just submit our simple form and move on with your day!

Predictive Maintenance Solutions by Omron

Whether retrofitting existing equipment or planning for a new production line, Omron and Airline make it easy with a large selection of predictive maintenance products for a variety of applications. Our solutions can help you:

1. Maintain regular operations and avoid disruptions caused by equipment failure

2. Reduce operating expense by providing maintenance only when needed with condition monitoring and analysis

3. Reduce added costs and impact associated with the skilled labor shortage

FEATURED PREDICTIVE MAINTENANCE TECHNOLOGIES

Maintenance Strategies Explained

Reactive vs. Preventive vs. Predictive Maintenance

Did you know up to 93% of companies consider their maintenance processes not very efficient? This uncertainty carries a hefty price point, as poor maintenance processes can reduce production capacity by 20%! The maintenance world is ever-changing with new strategies and technologies, so keep reading to learn the pros and cons of reactive, preventive, and predictive maintenance so you can make informed improvements.

FEATURED TECHNOLOGIES

Repair, Refurb, Retrofit, or Replace?

How to Handle Machine-Down Situations

Several options exist to get your system back online, bringing it back to its initial state or even better than before. So should your machine simply be repaired, or will retrofitting or replacing your unit yield the most benefits in the long-term? Keep reading to learn the benefits and best applications of each option.

.jpg?width=200&height=180&name=OLF%20info%20th%20rev%20(003).jpg)