Liquid & Gas Booster Systems & Components

system builds • haskel & Butech distributor • repairs

Skip to a section

Applications

What are LIQUID & GAS BOOSTER systems used for?

Airline & Haskel high pressure systems are used for a variety of industries and application, including (but not limited to):

• Low pressure gas reclamation

• Nitrogen compression

• High pressure liquid chromatography

• Hydrogen fueling

• Cannabis extraction

• Helium blanketing

• Super critical CO₂

• Pressure testing

• Cylinder filling

• Oil & gas

• Plant air amplification

• Refrigerant recovery

• SCBA refilling

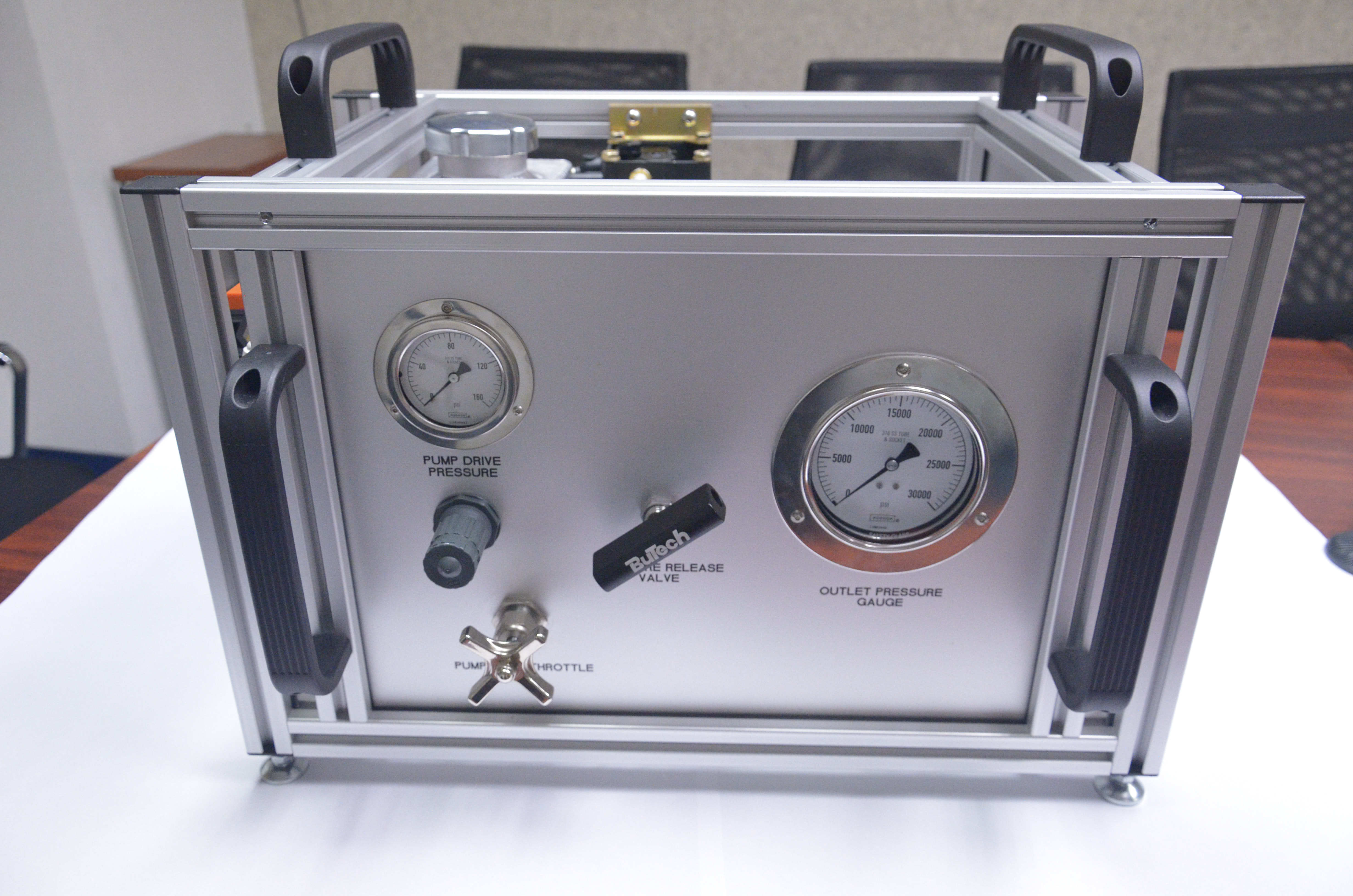

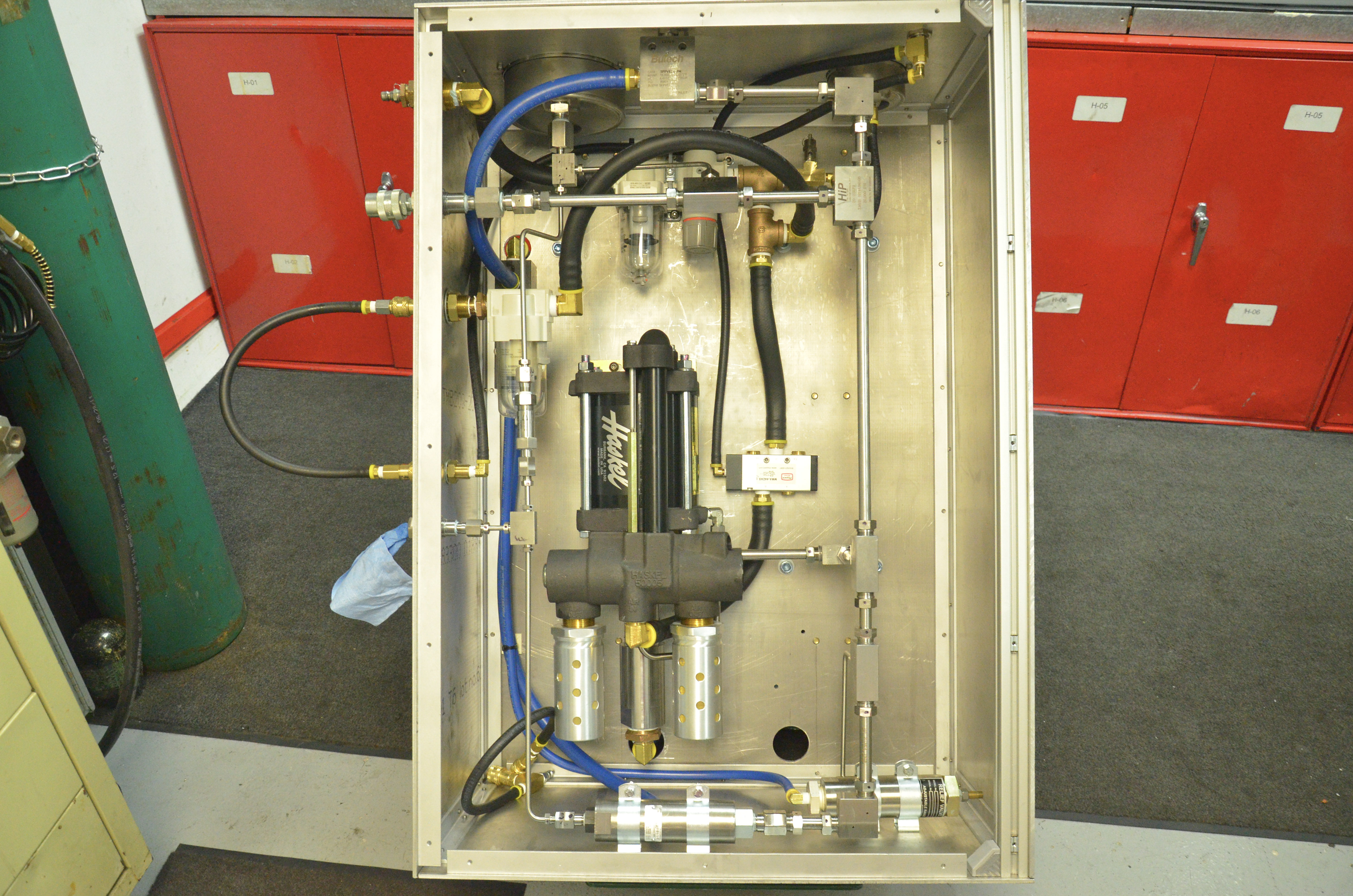

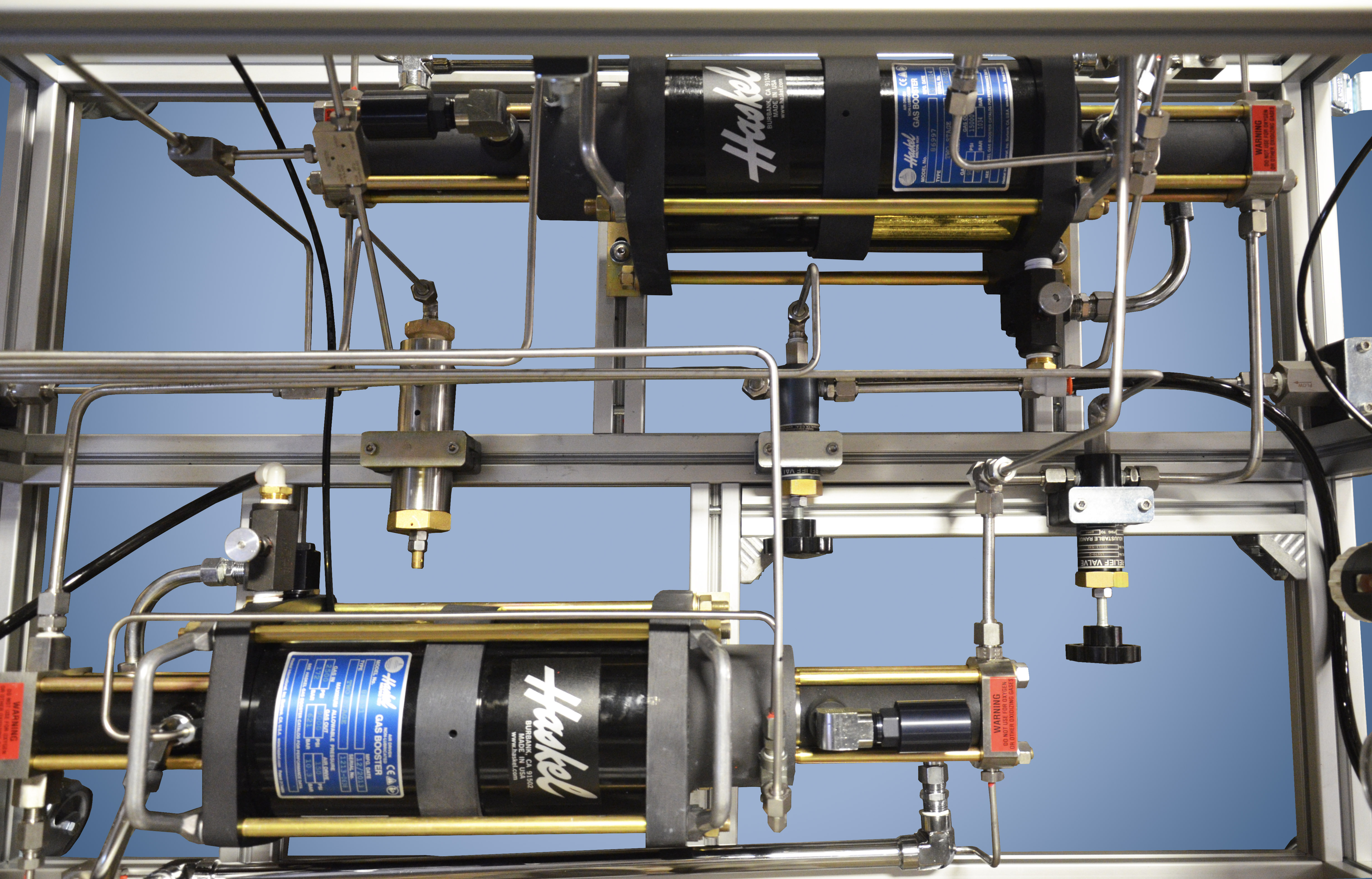

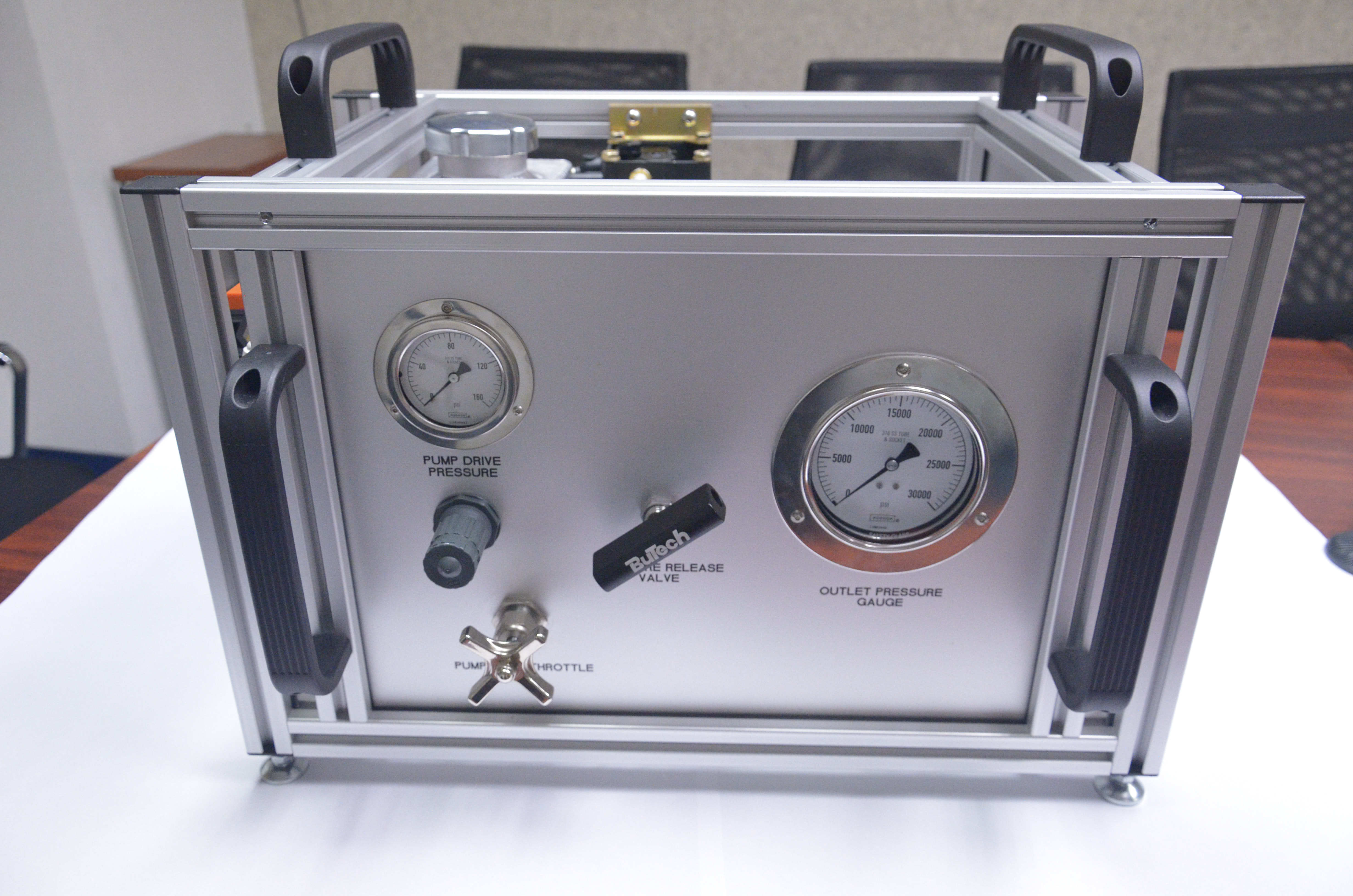

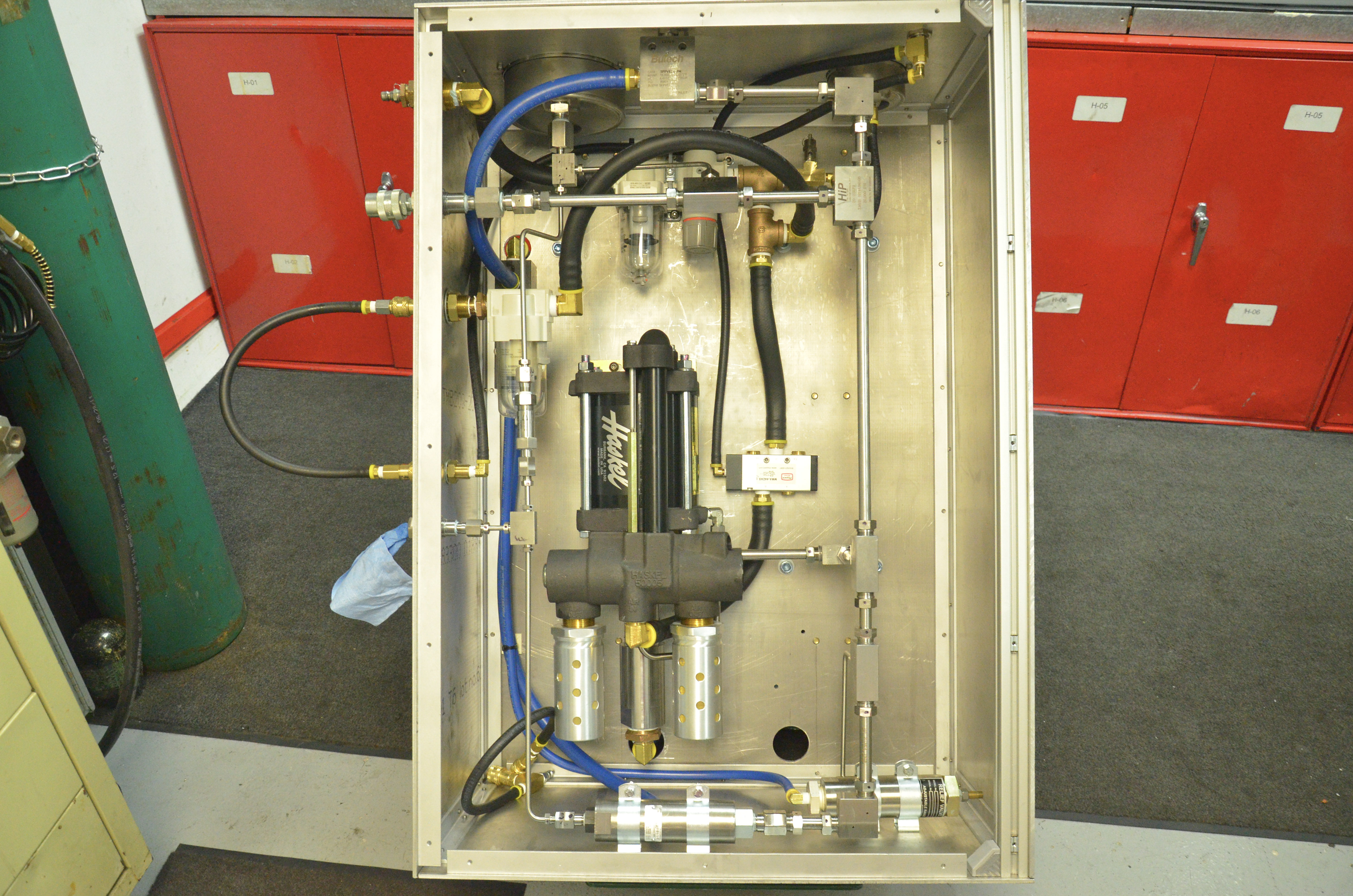

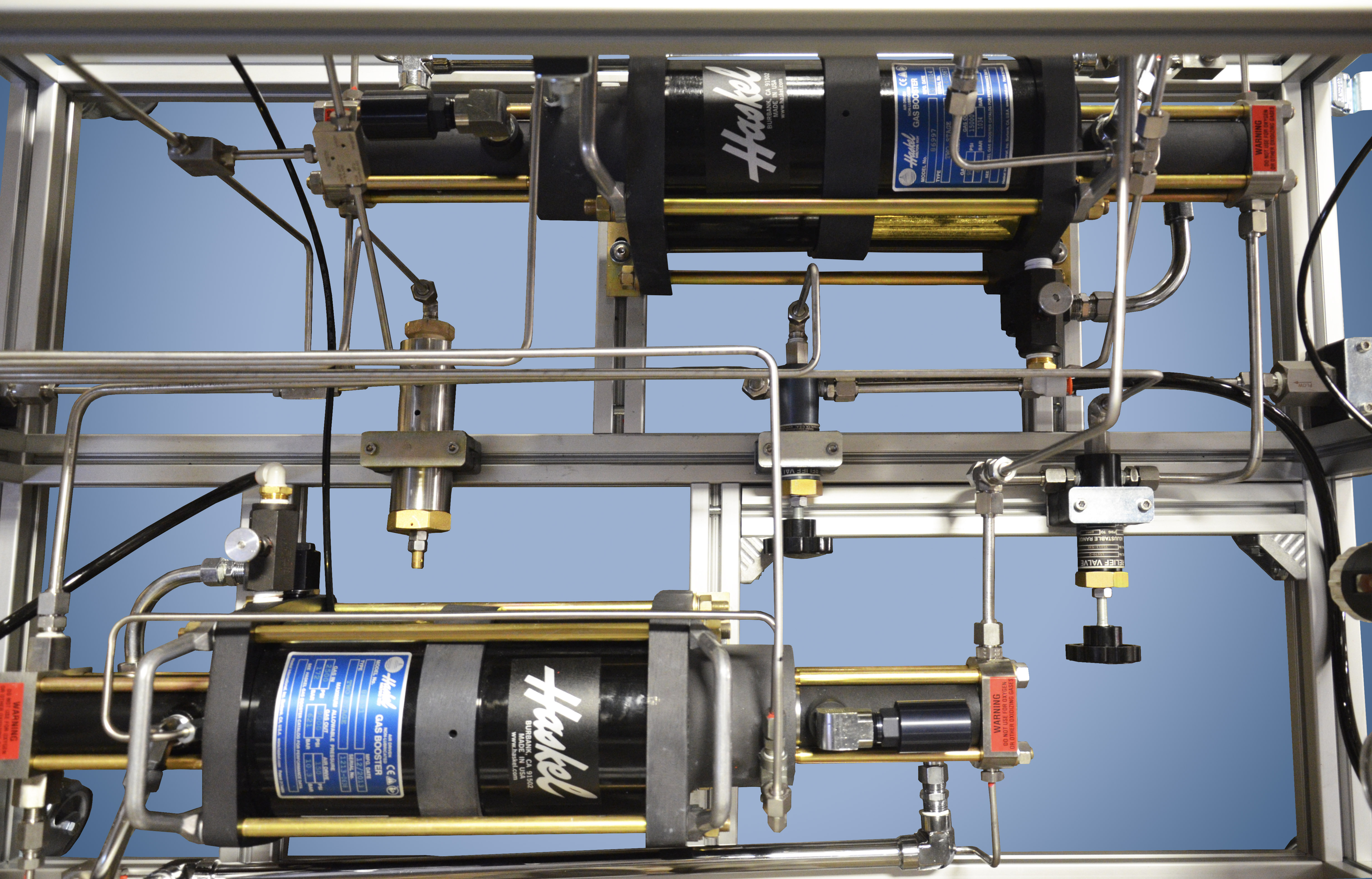

When you need to boost the pressure of compressed air, liquids or gasses (such as hydrogen, oxygen or argon), we're your one-stop-shop solution. Airline can custom design and build turnkey booster packages, for any industry, integrating components including:

• Haskel air pressure amplifiers, liquid pumps, or gas boosters• Pressure piloted drive air controls

• Safety relief valves

• Inlet and outlet filters and gauges

• Roll bar frames made of extruded anodized aluminum

High-quality turnkey systems from start to finish

Let us know your specific needs, and we can handle the rest.

Consultation & Concept

We’ll visit your facility (or have a virtual discussion) to meet with you and determine your requirements.

Design & Engineering

We’ll recommend a solution and a quote a price and timeline. Once approved, our design group will kick into gear and provide you with a system schematic.

Manufacturing

Our trained staff will build the system in our ISO 9001:2015 certified facilities.

Installation

We can quote installation and start up of your system.

Get your system started today.

or call (215) 900-5743

As an authorized repair facility for Haskel, our factory-trained repair technicians have years of experience evaluating and repairing Haskel components and systems. We use authentic factory parts to ensure that our repair replicates the performance of your original unit. Airline can quickly evaluate and repair:

• Air & hydraulic-driven gas boosters

• Air-driven liquid pumps

• Air pressure amplifiers

With Airline's Red Pallet program, submit your repair request online, or give us a call at the number below. We can arrange the shipment of your unit for repair, or if you're local to our locations, can even pick up and deliver your repaired equipment.

Get your repair submitted today.

or call 1-800-999-7378

or, for the do-it-yourself types

Watch our Tutorials

How To Replace Seals on Haskel .33 HP Pumps

This tutorial explains how to repair the Haskel 1/3 hp pump series, and how to disassemble the pump, replace its seals, and assemble the pump back together again. This tutorial applies to the entire Haskel pump series, including the M, MS, 29723 liquid pumps, as well as the HAA air amplifier series. As mentioned in the tutorial, you can find your pump's seal kits and assembly drawings by typing the series into the search bar at www.airlinehyd.com

Watch more explainers & tutorials

Shop all of our high pressure components.

New!

HASKEL Q-DRIVE

Introducing an electric servo drive compression system, engineered with the reliability and safety you expect from Haskel. Q-Drive creates new advantages by revolutionizing gas boosting with proven technologies. It combines Haskel’s 75 years of compression experience with electric servo drive technology that has been in use for over a decade in industrial and scientific applications. These electric servo drives allow Haskel to replace hydraulic cylinders with a technology that is: quiet, compact, efficient, reliable, low maintenance and infinitely controllable. Haskel has brought these two technologies together in the Q-Drive to ensure unmatched value and best in industry performance.

HASKEL AIR PRESSURE AMPLIFIERS

Are You Under Pressure to Raise Your Air Pressure? In most industrial plant settings, it is extremely common to encounter situations in which the standard air compressors in the facility are unable to deliver pressures high enough to properly service a variety of industrial operations, processes, and production equipment. What options are available when these circumstances are encountered? Initial instincts lead one to consider an investment in an air compressor capable of producing output pressures beyond those of conventional air compressors until one learns about the high price of such units...

WHEN YOUR APPLICATION DEMANDS "MORE PRESSURE! MORE PRESSURE!"

Ok, so you’ve run through the initial calculations necessary to determine the hydraulic pressure needed to satisfy the requirements of your application and double checked your math. And now you realize the hydraulic pump and system components you were hoping to use just won’t cut the mustard. Your application demands hydraulic pressures in excess of the pressures for which the hydraulic pump and system components are rated for safe operation. To purchase a custom-built...

GETTING THE MOST OUT OF YOUR PROPANE OR BUTANE EXTRACTION SYSTEM

Butane, propane, or hybrid mixtures of these two solvents are used in one of the most common methods to extract oil from cannabis. An extraction system of this type will typically consist of a solvent supply/storage tank, similar in look to the propane tank that accompanies your outdoor gas grill; an extraction chamber, the location in which the solvent interacts with the cannabis; and a separator, where the extracted oil is separated from...

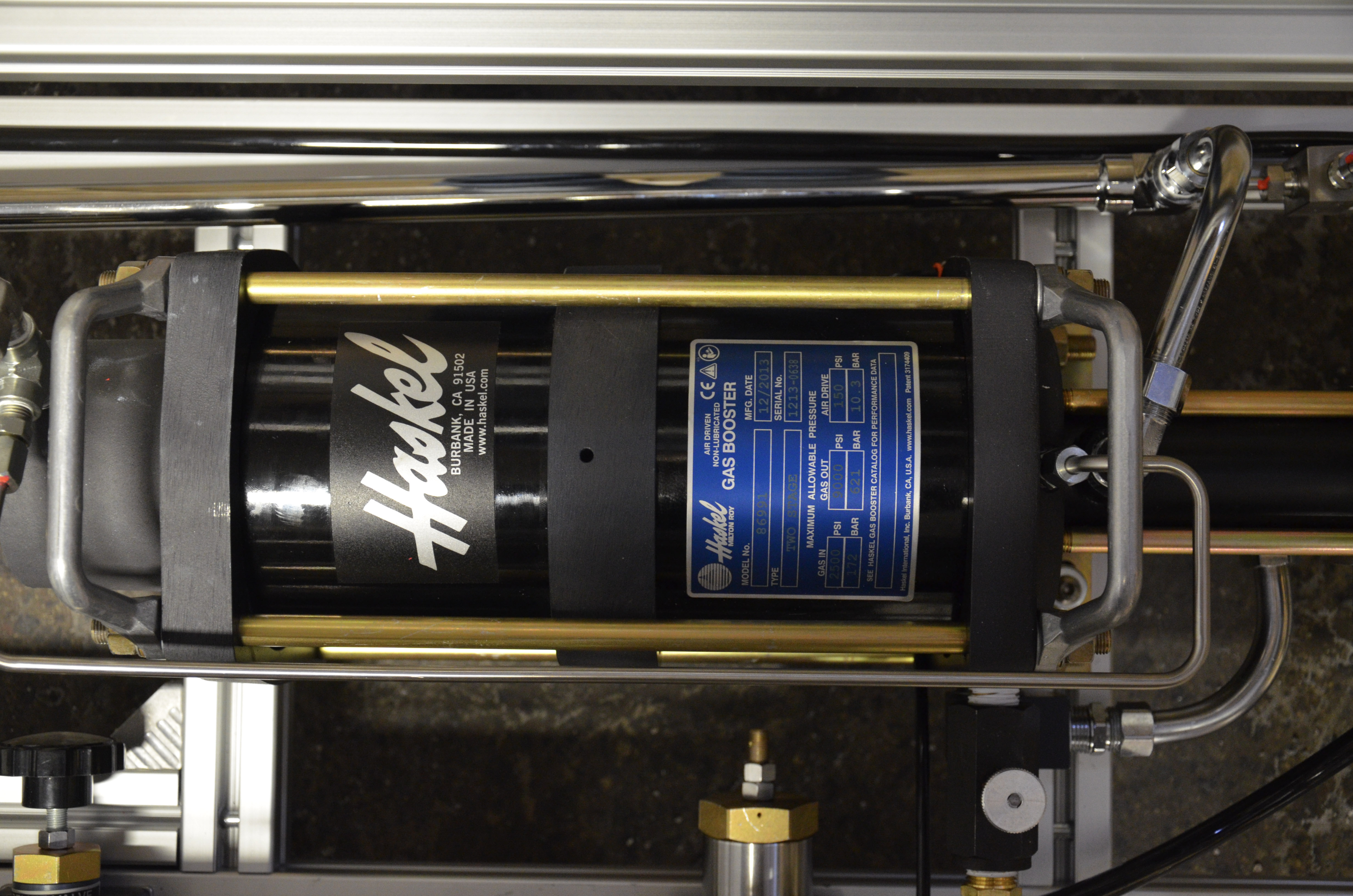

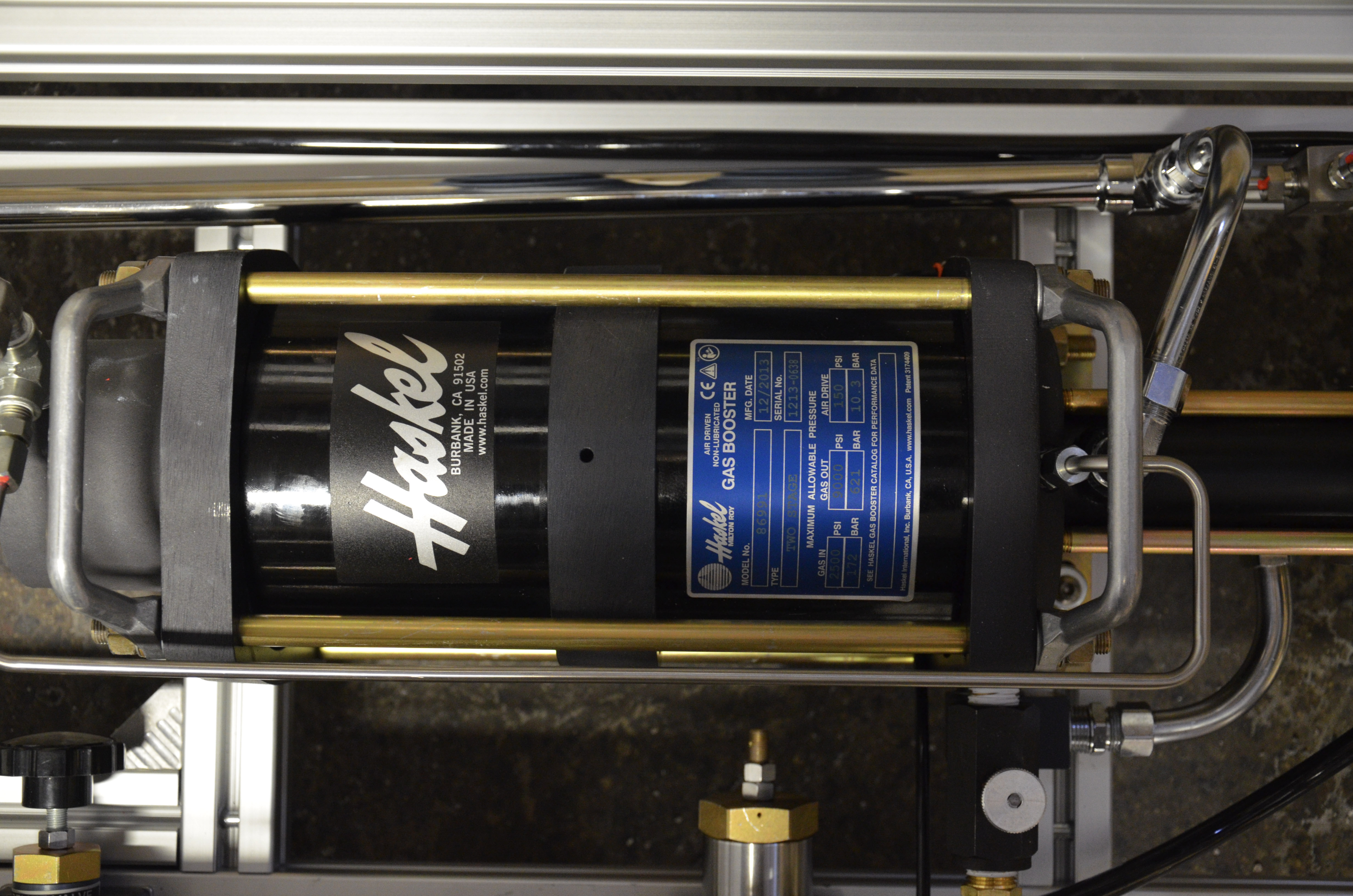

HASKEL GAS BOOSTERS

The use of industrial gases in many industries is commonplace and the demand for various types of industrial gases such as oxygen, nitrogen, hydrogen, and argon continues to rise. Some of these industrial gases are quite expensive and most are commonly delivered at pressures of 2,000–2,600 psi in steel cylinders. Unfortunately, due to the natural properties of many industrial gases and pressure limitations of the supply cylinder, users often fail to retrieve all the industrial gas that is contained within the cylinder...

Subscribe to our blog

Learn more in our blog, Technically Speaking.

Airline supplies a full range of hydrogen & compressed natural gas (CNG) handling equipment, including hydraulic and pneumatic-drive gas boosters. We also offer a range of high pressure valves, fittings and system components designed for operation in hazardous locations. Pneumatically driven and controlled systems are intrinsically safe and require no electronic components. Airline offers rental boosters for proof pressure testing of hydrogen or CNG system plumbing.

Markets and Applications

• Hydrogen fueling & filling stations

• Hydrogen compression, storage, and transfer

• Hydrogen generation

• R&D lab gas distribution

• Semiconductor manufacturing

• Vessel proof testing

• Fuel cells: mobile, portable, and stationary

Gas Booster Features and Benefits

• Designed for hydrogen gas service

• Range of modular double-acting, single-stage, and two-stage models allow compression up to 14,500 psi (1,000 bar)

• Reliable seal design for extended life

• CE marked and ATEX certified for the European market

• Designed for simple and easy maintenance

• High-efficiency design for minimal energy usage

• Hydrogen capacities from 25 kg/day up to 1000 kg/day.

• Flow capacity dependent upon application