This August we're sharing stories from our talented engineers in the technology fields of fluid power, automation, machine safety, and controls. Keep checking in, we're adding new articles and videos every week!

What Does An Engineer Do? Engineering Application Story

Our engineers seem to get asked this question all the time, “what do you really do?” That will of course depend on an engineer’s chosen discipline, their specialty within that discipline, and current job responsibilities/experience, but at its core, all engineering is problem-solving. Let’s take a look at one of our successful engineering applications as an example of what engineers do on a regular basis!

Engineering the Impossible | Building Over A Busy Highway🏗️

Rockefeller University (in Manhattan, NY) wanted to expand its campus, but the cramped city space forced them to think outside the box. Utilizing their air rights, they planned an ambitious expansion directly overtop of F.D.R. Drive, a busy, multi-lane highway. Leading to build time, one key question remained; How do you keep nineteen, 400-ton, pre-built structures completely level, while transporting them over the East River and into position? Well, that's why Federated Crane called Airline.

About Airline's Engineering

Did you know? Airline has a talented team of engineers who custom-design fluid power, automation, machine safety, framing, and control panels.

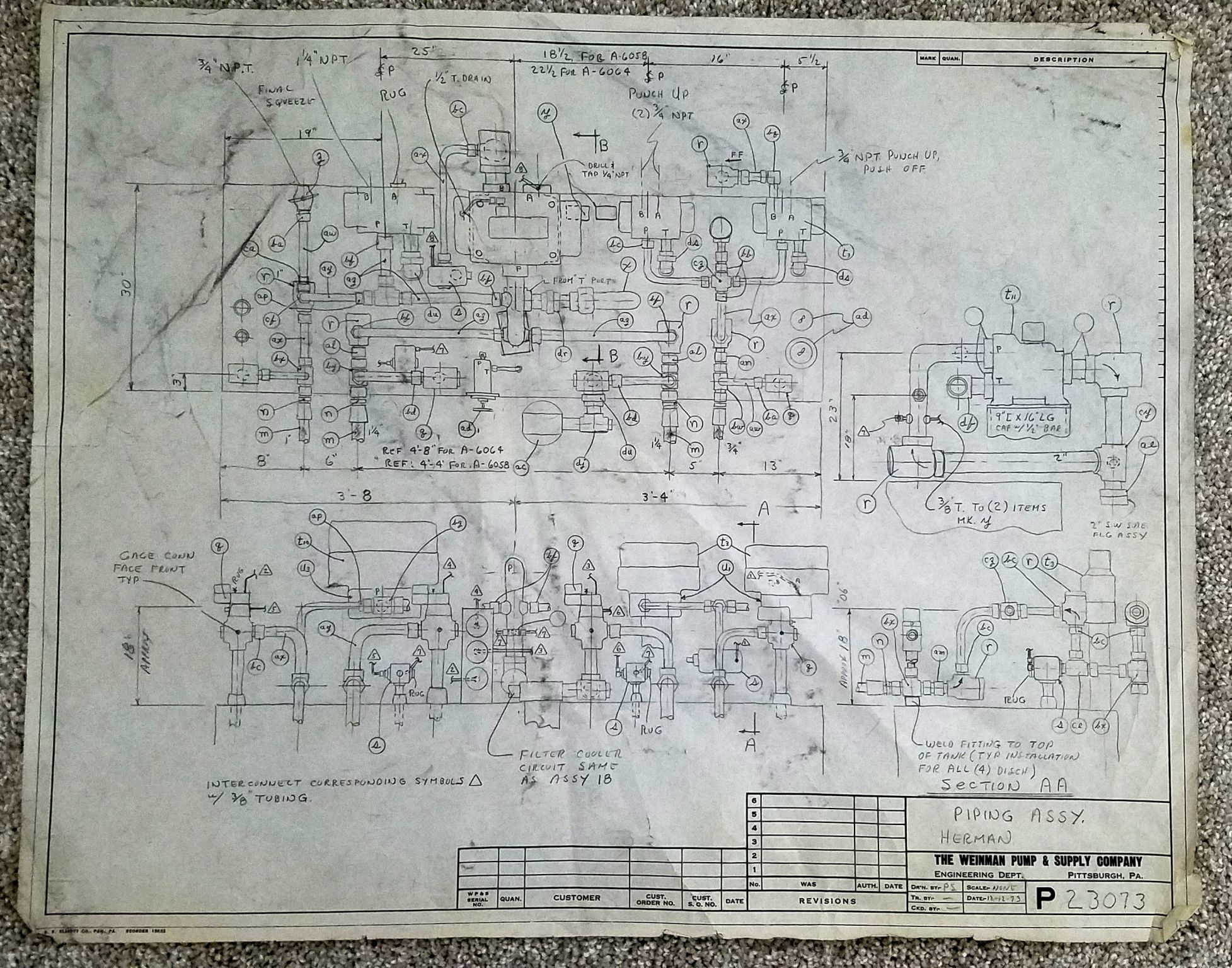

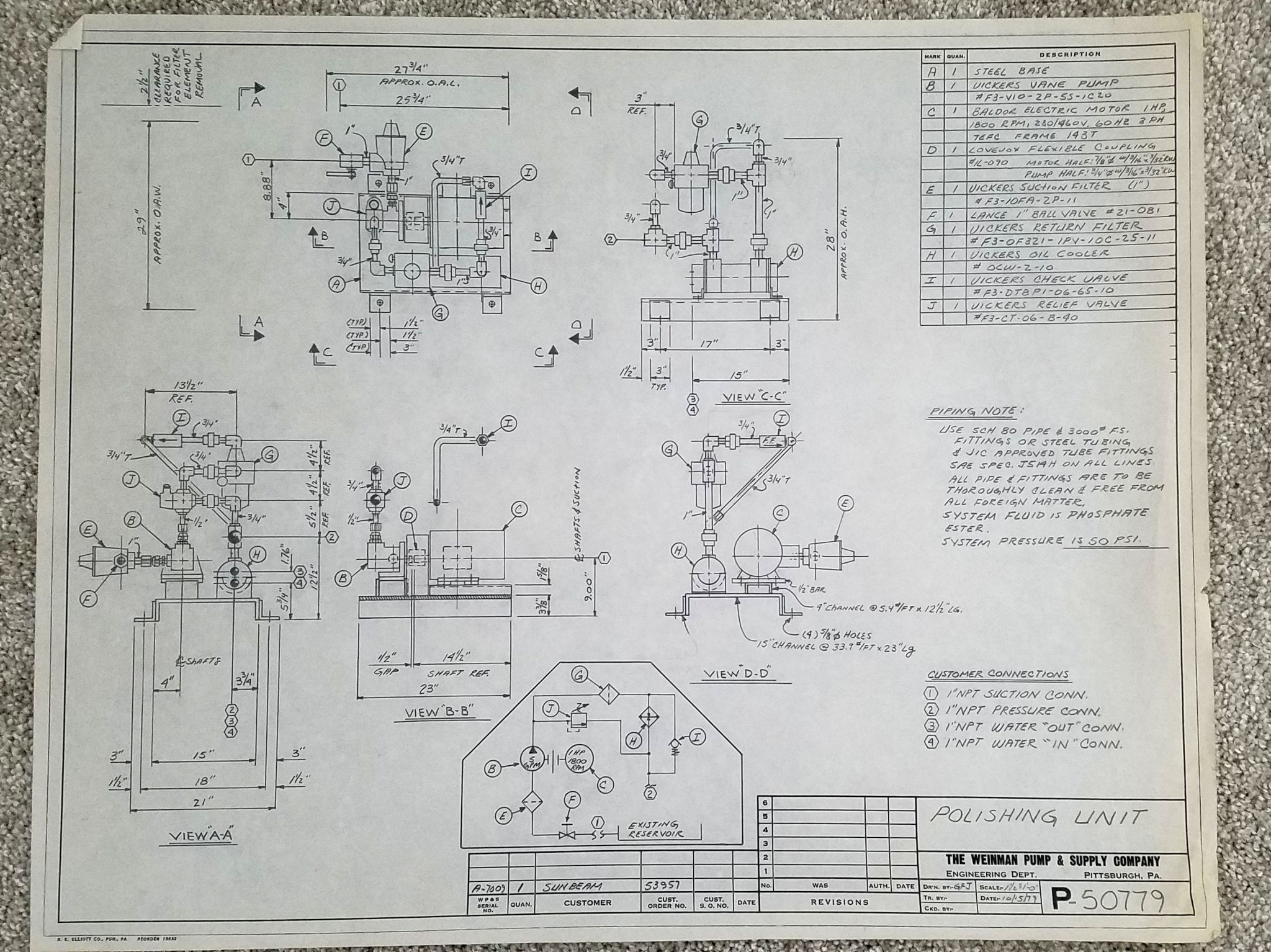

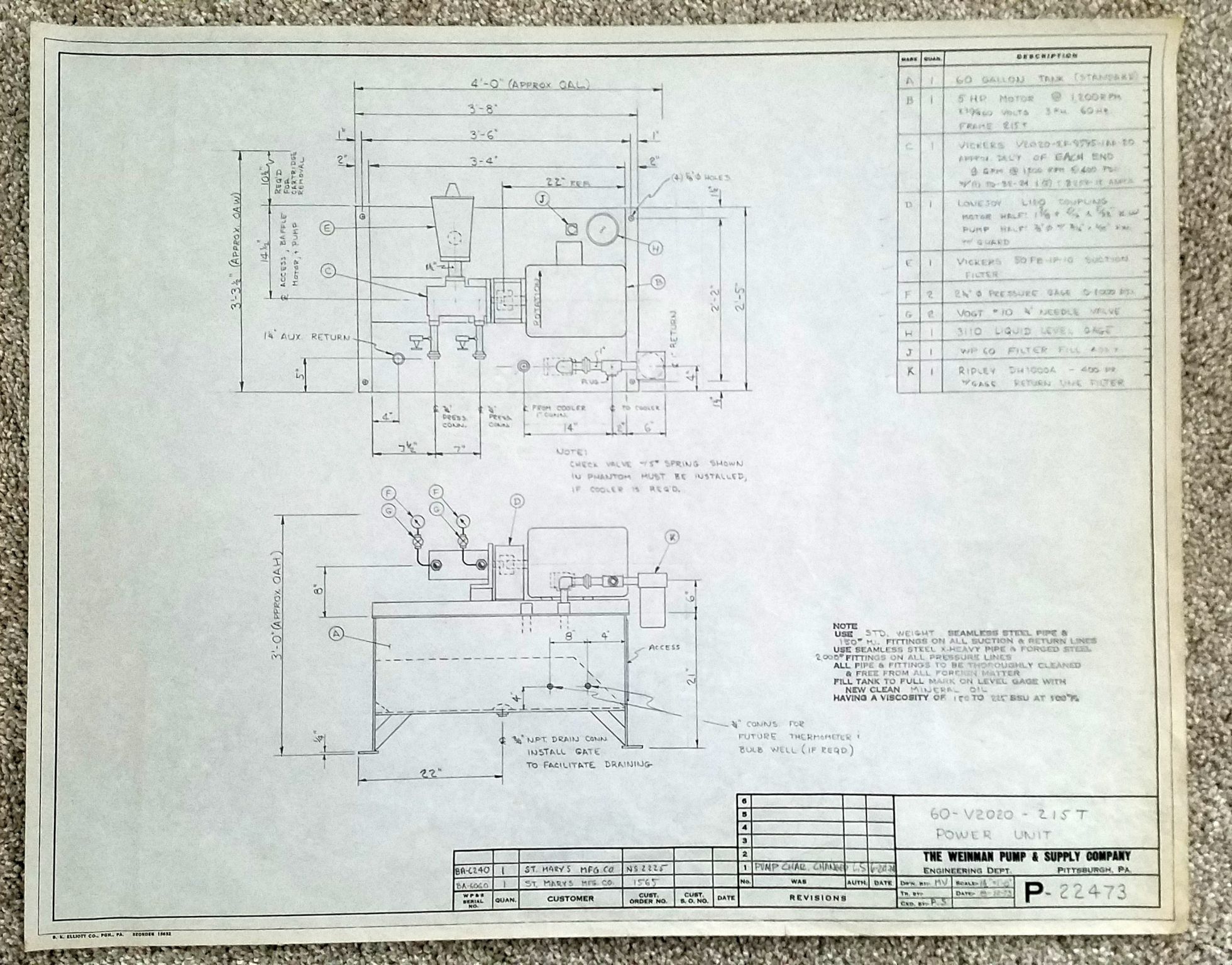

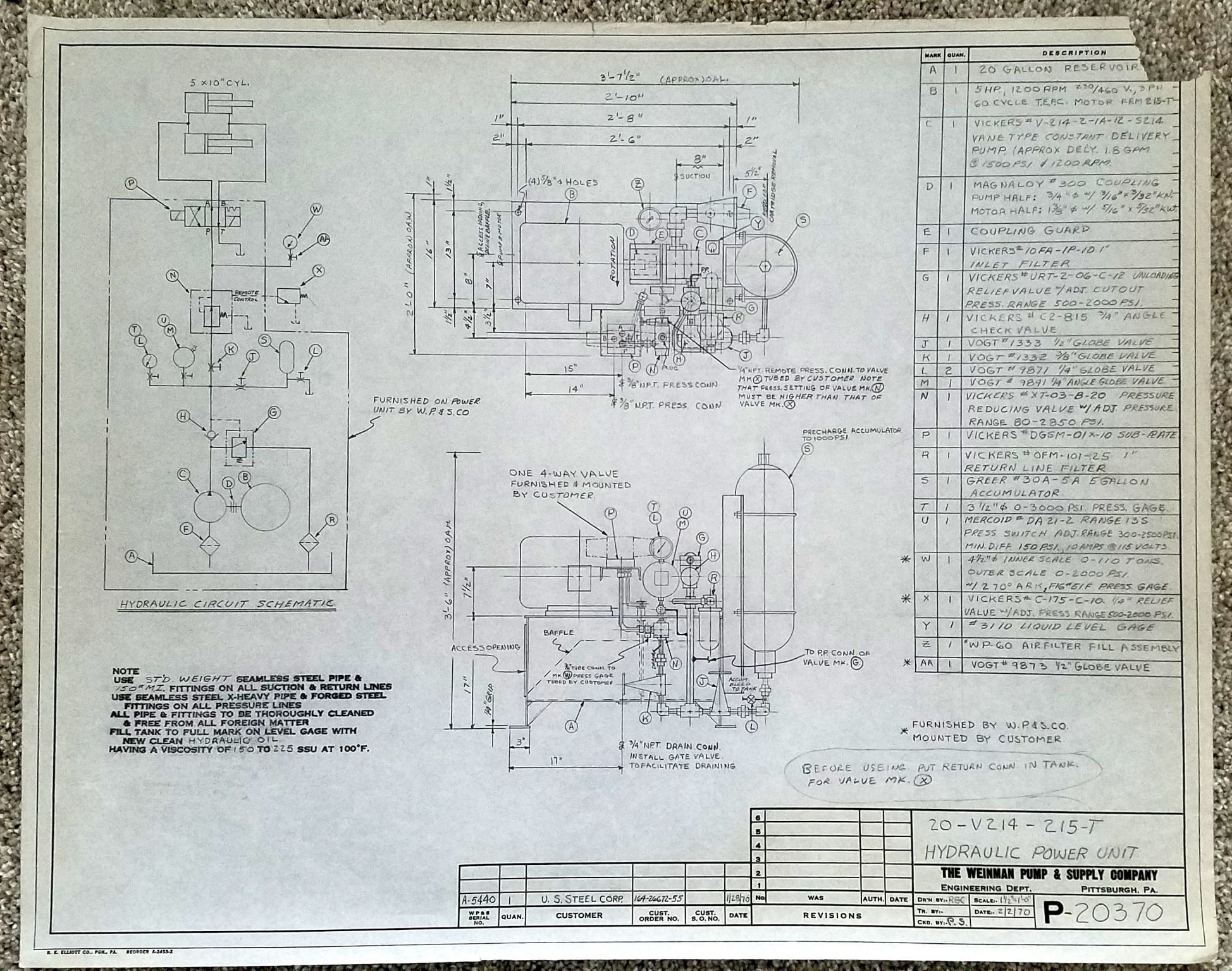

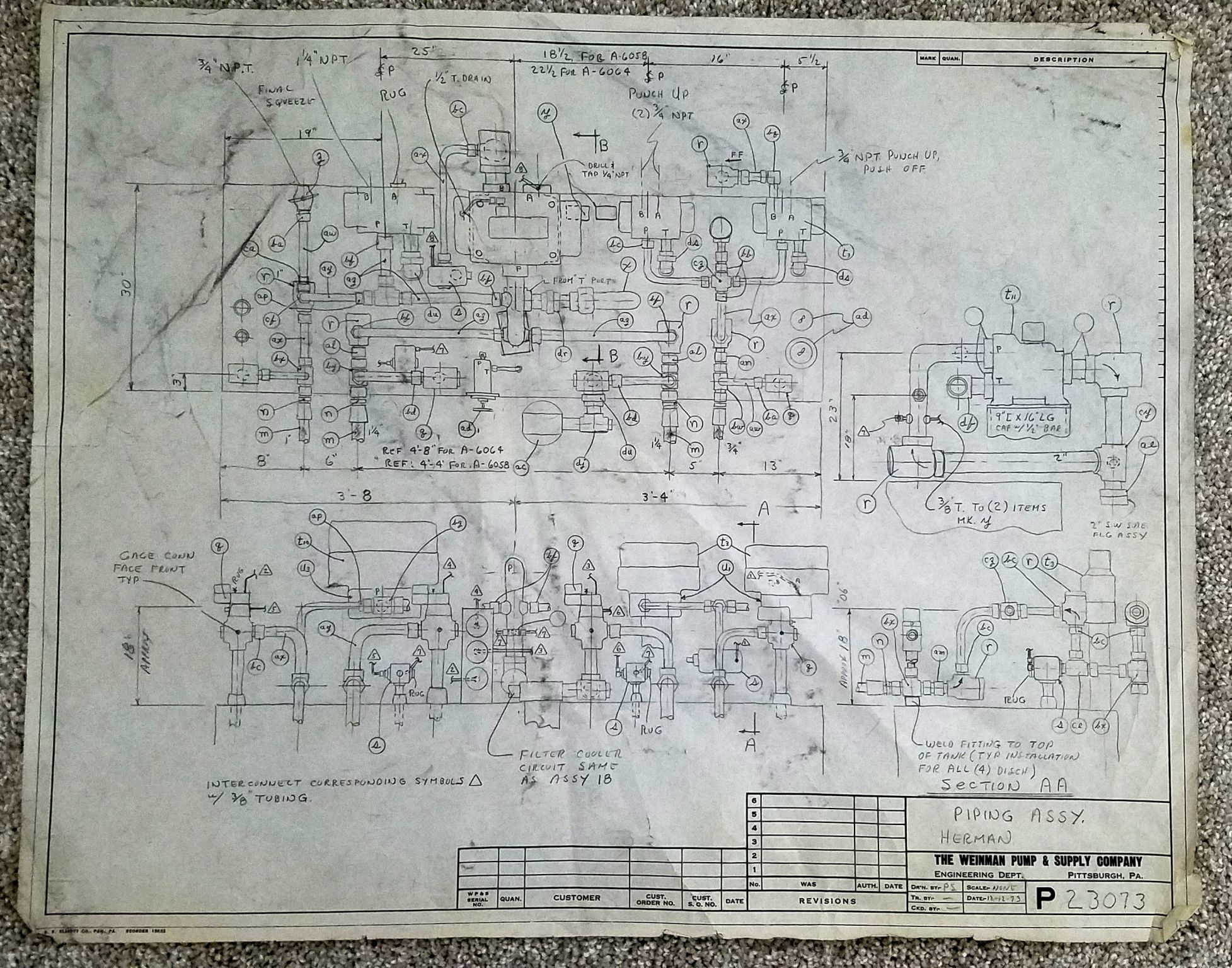

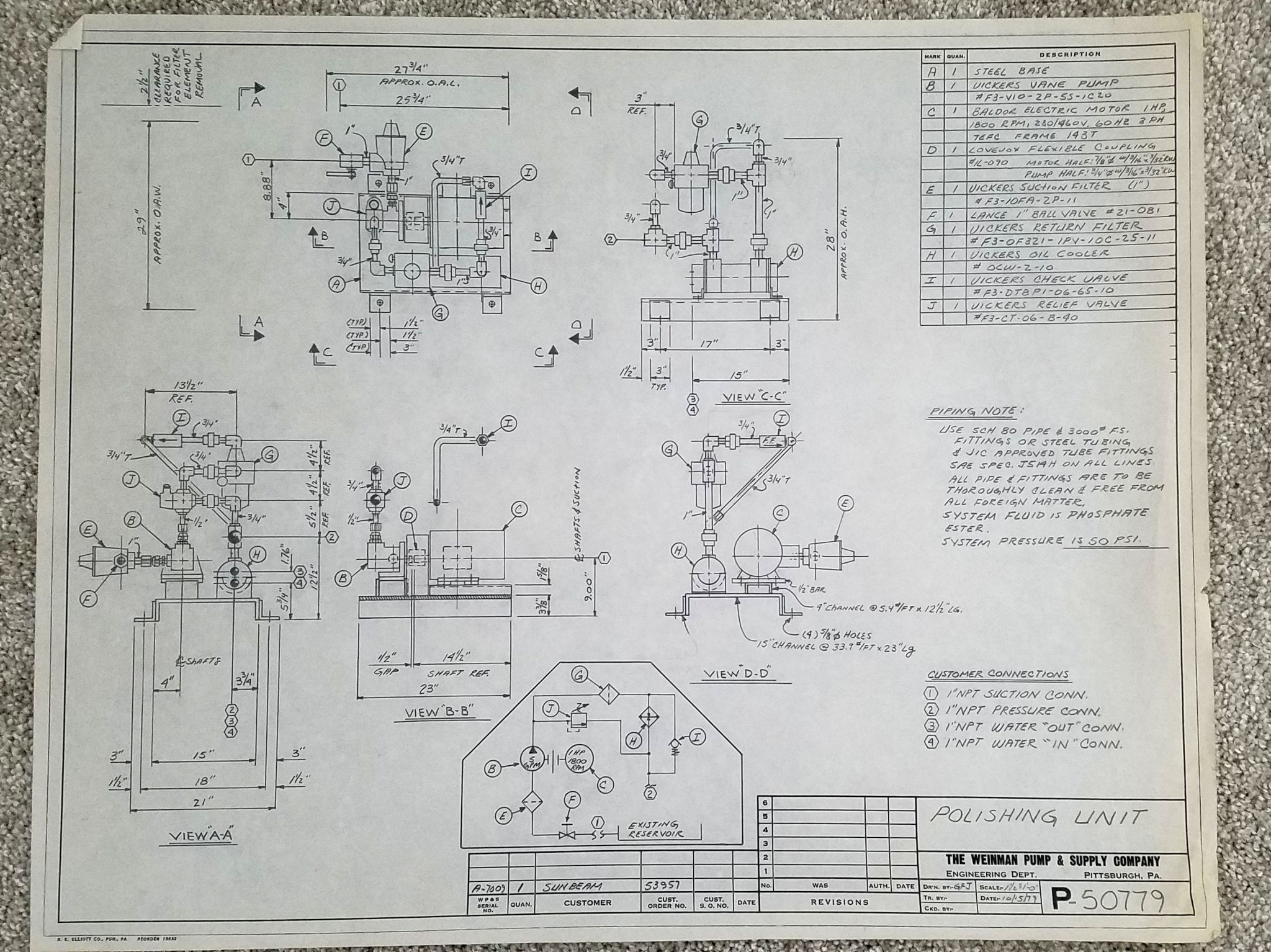

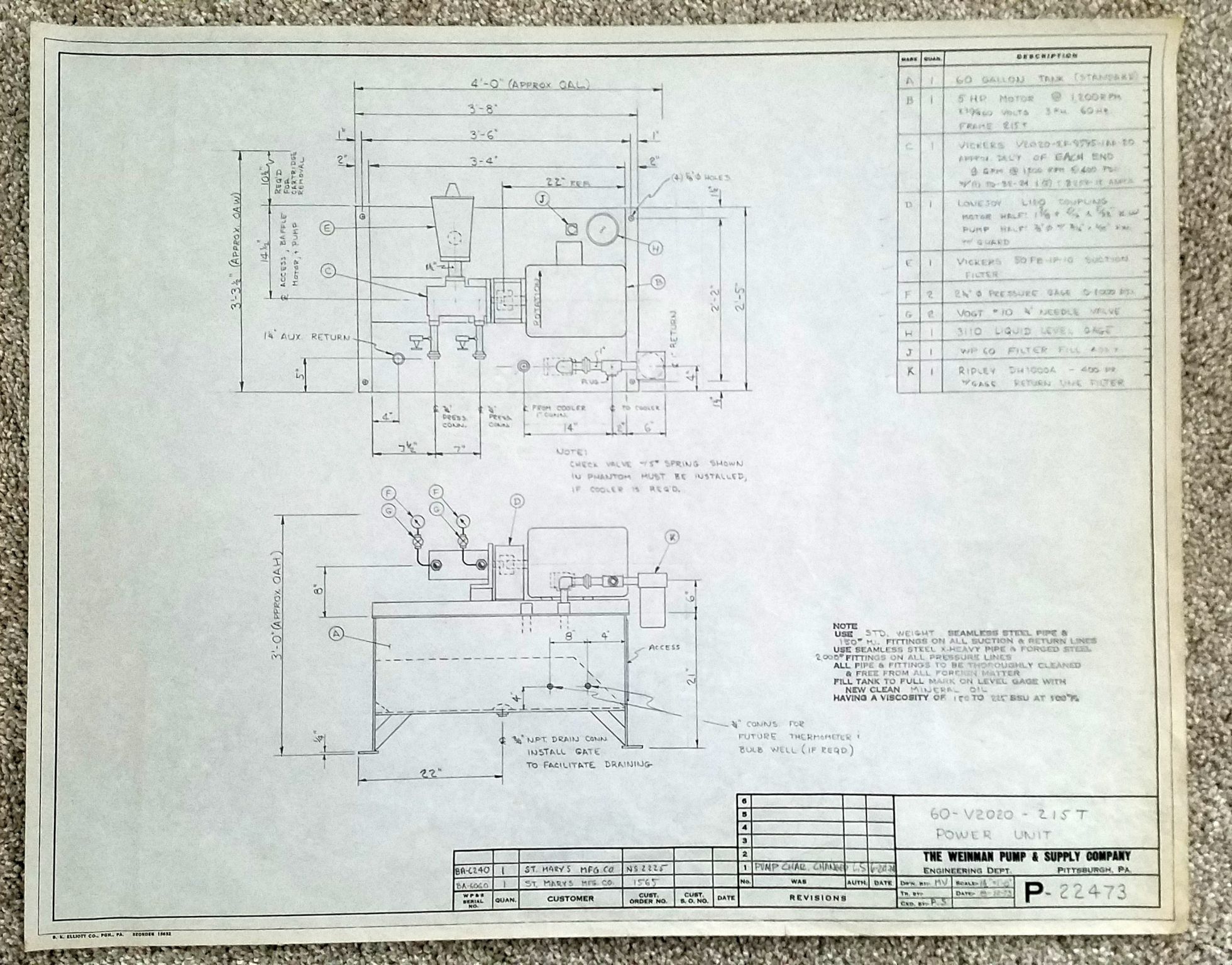

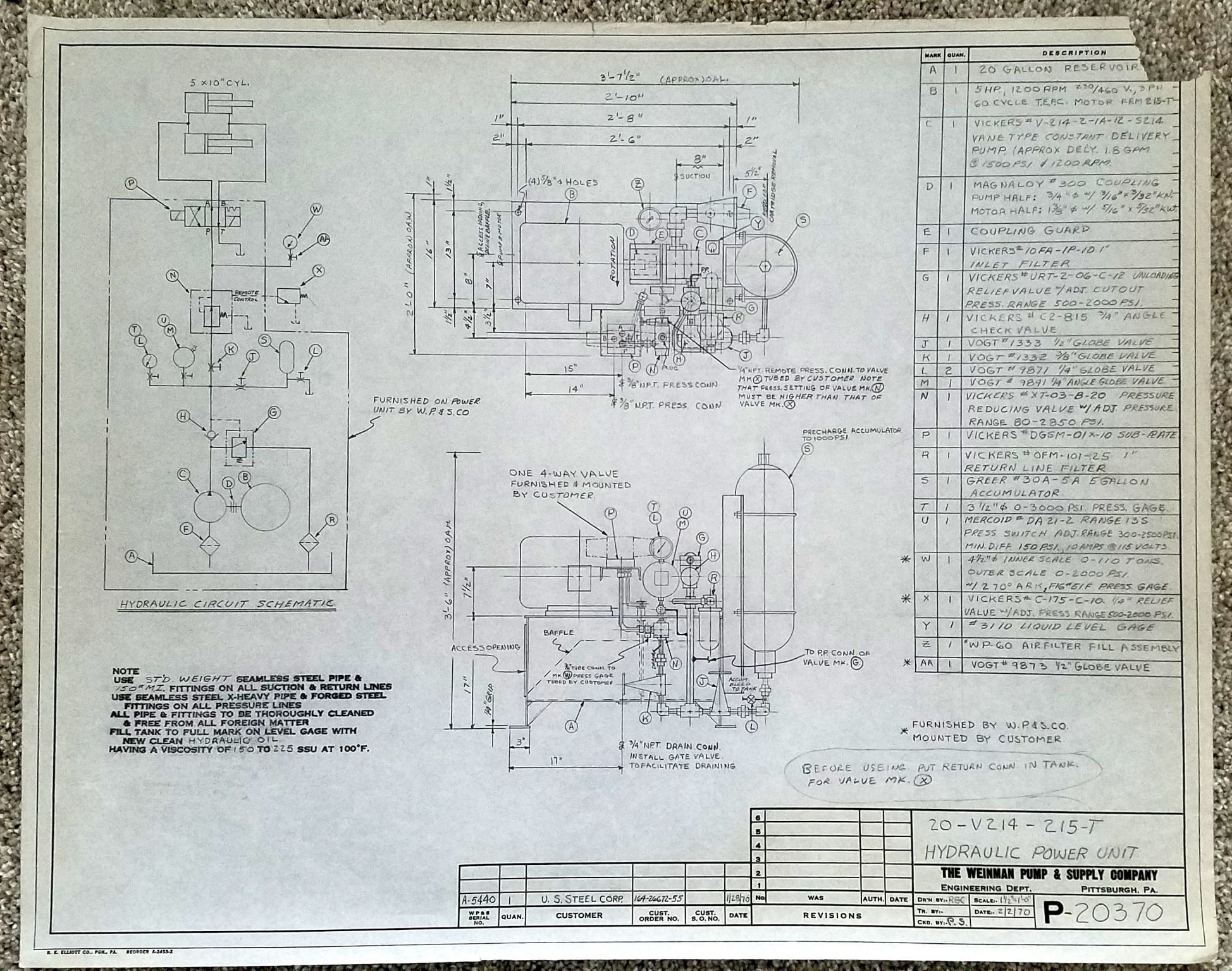

A true form of art!

These 1970s hydraulic schematics and layouts are all hand-drawn. One was even drawn by Airline's own George Johnson from his time at Weinman Pump!

Engineering Opportunities are Available at Airline

Airline Hydraulics Corporation is 100% employee-owned through our Employee Stock Ownership Plan (ESOP). Explore our careers, where employee happiness and professional development work hand in hand.

Lean Manufacturing Work Cell Reduces Cycle Time by 90%

Microlab, located in Parsippany, NJ, aimed to decrease its production cycle time and costs, so their Manufacturing Manager Tony Smith reached out to Airline's Darren Rist to discuss lean accessories, like flow racks, as a solution. But Tony soon realized that Microlab needed to go bigger to reach its full potential. In the end, Airline and Microlab's custom-engineered solution brought Microlab's cycle time down from 20 minutes to two minutes, a whopping 90% reduction! So how did they do it? Keep reading and watch their video success story.

Meet our Machine Safety Engineering Team

Our MPSA Team combines expertise in corporate machine safety requirements, industry-recognized safety standards, technical problem-solving, mechanical and controls engineering, and more.

Custom-Engineered Solution Reduces Production Time by 64%

In today's fast-paced world, we're always seeking new methods to produce products faster, achieve higher quality, improve efficiency, and increase profits. Analytical Science and Technologies (AST), a laboratory solutions provider in Newton, NJ, accomplished just that with the help of Airline's custom engineering. For a product they provide to the semiconductor industry, not only did they reduce production time by 64%, but they also significantly reduced their product's size and weight (a huge benefit to their customers). So how did they do it? Keep reading and watch their video success story.

.gif)